Building Envelope Testing

Inconsistent temperatures. Rooms that cannot be sufficiently heated or cooled. Unresolved indoor air quality issues. Sometimes, the problem isn't in your heating and cooling systems, but in the air tightness of your building. To get to the bottom of it, you need definitive answers. That's where Eastern Air Balance Corporation's Building Envelope Testing can help.

Inconsistent temperatures. Rooms that cannot be sufficiently heated or cooled. Unresolved indoor air quality issues. Sometimes, the problem isn't in your heating and cooling systems, but in the air tightness of your building. To get to the bottom of it, you need definitive answers. That's where Eastern Air Balance Corporation's Building Envelope Testing can help.

We employ the most effective testing methods to identify areas of leakage in your building envelope and provide a detailed plan for remediation. Everything you need to implement our plan is there - from volume calculations to complete systems analysis - to equip you with the knowledge you need to improve your building's efficiency, lower operating costs and improve occupant comfort.

Always on the forefront of testing, adjusting and balancing services, Eastern Air Balance Corporation is leading the industry in developing building envelope testing methodology. Let us help you ensure the most efficient design and construction of your building for energy savings that will continue to offer a payback well into the future.

In-Depth: Building Envelope Testing

In-Depth: Building Envelope Testing

Proper measurement and control of outside airflow rates can lead to significant energy savings and improved comfort for many buildings being designed in today's marketplace.

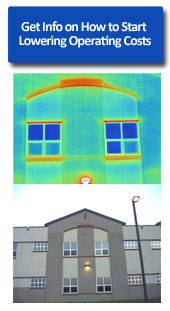

Building Envelope Testing is a test procedure that can be implemented to help determine the air tightness (efficiency) of the building envelope. Standard test procedures that are included in the Building Envelope Testing process include Building Pressurization Testing and Thermal Imaging.

About Building Pressurization Testing

Building Pressurization Testing can be performed by utilizing the building HVAC systems, operating on 100% outside air to pressurize the building to specific operating pressures with reference to atmosphere, measuring the actual airflow rate that is required to achieve the test pressure and determining a CFM per Square Foot Leakage Factor. Another method that can also be used is the Blower Door Test which depressurizes the building. Utilizing the Blower Door Method, the building is depressurized to a specific pressure with relationship to atmosphere and a CFM Per Square Foot Leakage Factor is again calculated. ASHRAE recommends that the building be pressurized / depressurized to 0.016" w.c. with reference to atmosphere, while the Department of Defense requires a building pressure of 0.30" w.c. be achieved. For the most accurate results it is recommended that the test be conducted at several different pressures to determine if the CFM per Square Foot Leakage Factor is consistent. If the leakage factor stays the same at varying pressures the problem is most times indicative of a building envelope issue. If the leakage factor changes as the actual building pressure changes, this is most times indicative of an issue with control of the building automation system.

It is important to note that outdoor wind velocity can impact actual test results. Building Pressurization Tests should not be conducted when the actual wind speed is above 4 mph. Actual outdoor temperatures can also impact test results. For best results, actual outside temperatures should be between 35oF and 95oF. If the actual outside temperature is below 35oF there is a risk of damage by freezing pipes. If the temperatures are excessively high there is a concern of damage to the building finished materials.

About Thermal Imaging Testing

Thermography Testing or "Thermal Imaging" is a test procedure that is effective in identifying specific sources of infiltration and exfiltration through the building envelope. A "thermal imaging camera" is the technical name for a device that is utilized to measure and record the amount of heat radiating from or reflecting off a particular object. Thermal imaging is not a new technology. It has been utilized successfully by both the military and private sector for the past fifty years. When the technology is properly applied, a thermal imaging camera is a vitally important, nondestructive tool used to help analyze the efficiency of a building envelope. It provides a qualified technician the ability to see and analyze things that cannot be seen with your eyes alone. What this means is that an inexperienced technician with an inferior quality camera would not have the expertise and experience to interpret what the images are really showing and directly relate those images to the design of the building. In most cases, inexperienced/untrained folks add to the confusion and suggest remedial work that does not solve the problems.

Thermal imaging cameras do not actually see anything. Every object that is being photographed emits a certain amount of radiation. Energy is radiated from any object in proportion to its actual temperature. The more energy that is emitted from an object the higher the temperature. As an object becomes warmer it radiates more energy. The camera sees this change and converts it to a thermal image.

Most of us have used a camera of some type to take "normal" visible image photograph. There are several factors that are equally important and to producing a quality "visible image" or a quality "thermal image." These include "focus" which provides the required level of clarity and detail for the image, contrast which for a thermal imaging camera provides a thermal image within the acceptable temperature operating range of the thermal imaging camera and brightness that provides an image within an acceptable "thermal level" or in other words a sufficiently high enough temperature differential from inside to outside or outside to inside of a building depending upon where the thermal image is being taken. In order for the thermal image camera to provide the highest quality image for analyzing a building envelope's efficiency, the differential temperature from inside to outside should be a minimum of 15oF. For instance a space is maintained at 72oF during normal occupied hours. If the thermal image is being taken from the outside of the building to try and determine areas of infiltration the ambient outside temperature should be 57oF or below.

Two other factors that significantly impact the quality of the thermal image are "emissivity" and "reflectivity." Emissivity describes the efficiency with which an object radiates heat. Emissivity is measured on a scale of 0.0 to 1.0. Shiny metal for instance has a very low emissivity (0.05) while painted or oxidized metal has a much higher emissivity (0.94). Reflectivity is the ability of an object to reflect energy. Reflectivity may cause some thermal images to be confusing, as the reflected energy displayed by the thermal imaging camera may not always be directly related to the actual temperature of the object being photographed.

The technician photographing the thermal images has to be aware of these two important factors and make the necessary adjustments to the camera setting based on the known emissivity and reflectivity of different materials. Just because you can see an object does not mean that you can accurately measure its temperature. You need to fully understand the limitations of a thermal imaging camera to obtain an accurate thermal image.

There are two types of thermal images that can be obtained, "qualitative images" and "quantitative images." For the purpose of a Building Envelope Study "qualitative images" should be taken. In its simplest terms, a "qualitative image" seeks to measure thermal differences in a wall section, roof section, window or door. Properly adjusting the emissivity settings in the camera and a keen awareness of the actual reflectivity of the objects being photographed are key to a good image. The temperatures displayed in the thermal image do not have to be as exact, as the primary purpose of the image is to show a temperature gradient or differential temperature, not to indicate precise temperature measurements.

One additional factor that the impacts the quality of the thermal image that is captured is the IFOV or "instantaneous field of view." What this describes is the fact that the thermal imaging camera can see an object at a greater distance than it can accurately measure its temperature. The technician needs to be aware of and frequently check the distance to spot ratio while photographing. There is a chart furnished with the thermal imaging camera that details the distance that you can accurately measure the temperature of an object, and the smallest image size within the overall field of the lens that can be captured.

By utilizing both the Building Pressurization Test and Thermal Imaging Test, a trained, qualified technician can easily identify areas of leakage in the building envelope and provide a detailed plan for remediation which will lead to improved efficiency and lower operating costs.

|